Book Review: Solar Cycle Lumber Kiln

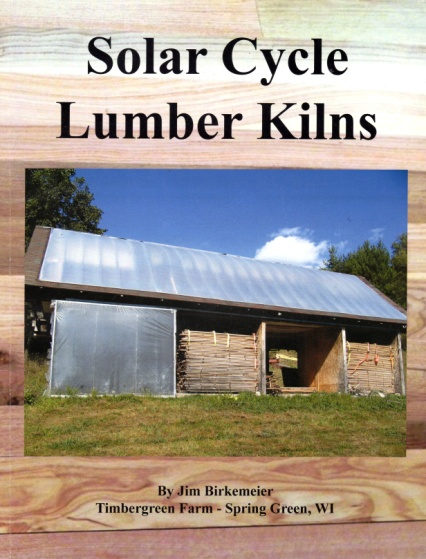

Author:Allen Yale | Organization:Tree Farmer and Committee Member | Date:March 1, 2018For those of you with sawmills, or who hire someone to do custom sawing for you, sawing is just the first step in turning logs into quality lumber. The boards have to be stickered, dried, and stored under cover. One of the ways to increase the income from sawn lumber, especially hardwood lumber, is to kiln dry it. Jim Birkemeier, a forester and woodland owner from Wisconsin has designed a kiln that is fairly inexpensive and which most saw mill owners could build. In his book, Solar Cycle Lumber Kiln, Jim gives detailed plans for construction of his kiln and explanation of the advantages of his design.

His design is fairly simple. It consists of a shed built on a concrete slab that is 10 feet by 44 feet. The shed is divided into 4 bays of varying widths from 10 to 14 feet wide. Both ends of each bay are open, but each bay is divided from its neighbor by an airtight insulated wall. Each side of the shed has an insulated door as wide as the widest bay. The south facing roof is the solar collector. In Vermont the slope of the collector/roof should be at an angle of about 45 degrees. Birkemeier uses 6 mil UV protected greenhouse poly film. When the sun is shining, the solar collected produces hot air that is conducted to the collector room in the attic space. From there a fan blows the hot air down into the chamber being kiln dried. The ideal location for the kiln is so that one of the long walls is facing south so that it gets full sunlight. It would be beneficial if the long side was also exposed to the prevailing wind so that lumber in the other bays could be pre-dried.

When I considered building a kiln, one of the factors that discouraged me was that, with many kilns, the lumber becomes case hardened and needs to be conditioned by adding moisture at the end of the process. This just seemed too complicated. Birkemeier claims that since his kiln works intermittently, drying only during daylight hours, it allows the lumber to acclimate during the night, preventing this problem.

I have cut some nice hardwood lumber and stickered it under cover. When I went to use it, there was hardly a board that wasn’t warped or cupped. I realized that I had not provided sufficient weight on top of my stacked lumber to keep the lumber straight as it dried. Because of that experience, I pretty much gave up sawing hardwood lumber. Birkemeier had a surprisingly simple solution, as he wrote: “the top 15-20 layers of the pile are strapped with 2” nylon straps to keep the entire stack flat as it dries.” [Four straps per pile] (p.8)

One of the nice features of the solar cycle kiln is the reduction of handling. The green lumber is stacked and stickered in one of the bays, about 3.5 MBF of lumber per bay. With the bay open to the air and wind, the lumber is air dried to about 12% moisture content in about three months. After air drying, the insulated sliding doors are closed on that bay and the hot air from the solar collector is directed into that bay. After about two weeks, the wood should have reached about 6% moisture content. Once dried, the lumber should be stored in a humidity-controlled environment, otherwise the ambient humidity would eventually return the lumber to about 12 % humidity. Birkemeier also has several plans for smaller solar kilns.

For anyone considering a kiln, I strongly recommend they take a look at Birkemeier’s book. Birkemeier, Jim, Solar Cycle Lumber Kiln, Spring Green Wi: Timbergreen Forestry, 2014. 61pp, $16.00.